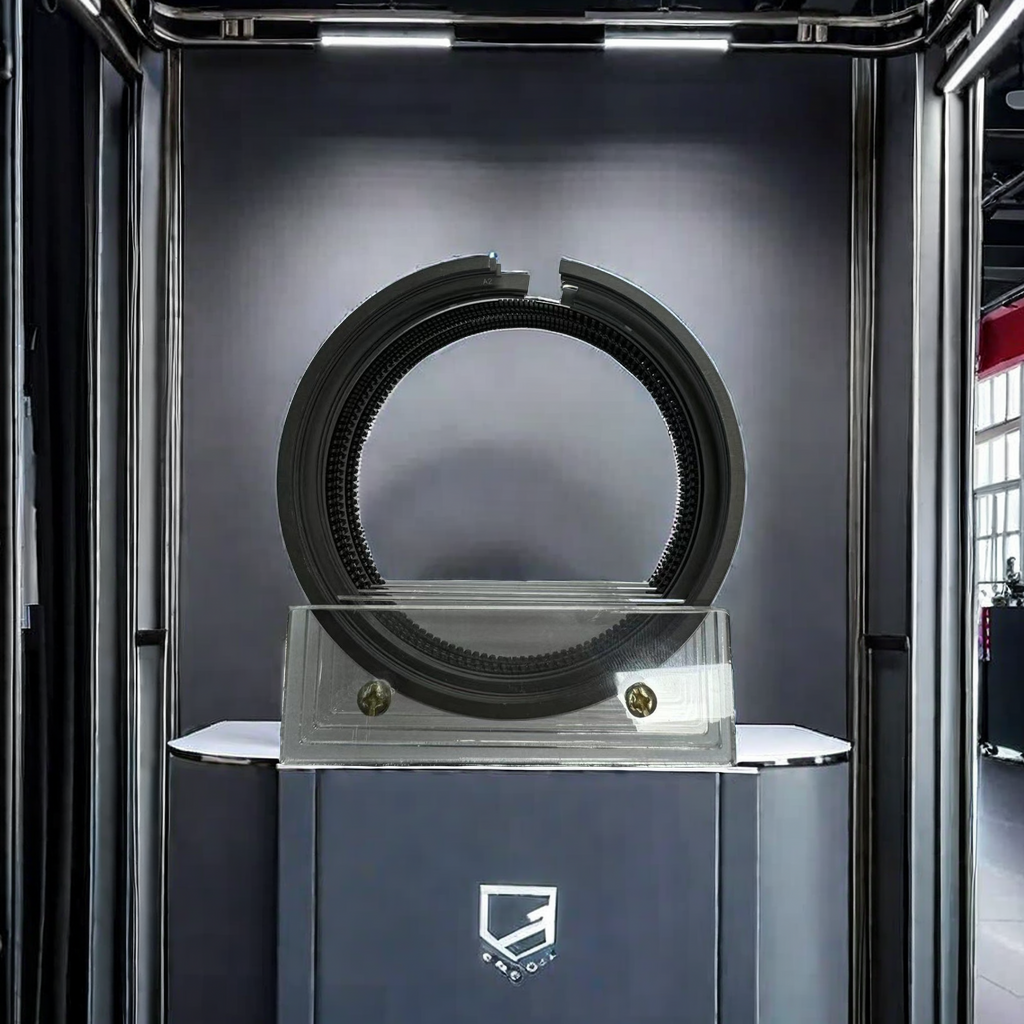

DhatSU DL-T F70V piston ring suit | 13011-87314A/13011-87317/31032 high quality durable car engine repair preferred accessories

In the core mechanical system of a car, the engine is like a beating heart, and the piston ring, which plays a key role in sealing, is an important component to maintain the continuous operation of this lifeline. As a classic work produced by professional auto parts manufacturers,DhatSU DL-T F70V piston ring suit (including 13011-87314A / 13011-87317 / 31032 and other specifications) has become the first choice for alternative expression in the eyes of numerous auto repair technicians and car owners due to its excellent durability and wide applicability.

The key guardian of the power heart: the importance of analyzing high-performance piston rings

Many people may not realize that the piston ring is not only related to the performance of the cylinder compression ratio, but also an indispensable part of controlling oil consumption, preventing combustion gas leakage and improving fuel efficiency. Once worn or broken, it may cause the risk of engine power reduction or even serious damage. Therefore, it is particularly important to choose a replacement product with excellent elasticity and compressive strength.

Why choose DhatSU DL-T F70V: a comprehensive analysis of the technical advantages of this piston ring

Unlike ordinary imitations on the market, DhatSU always adheres to high-standard manufacturing processes and combines advanced surface treatment processes to further enhance the wear resistance index. After long-term test verification, it can still maintain a stable working state under continuous high-intensity working conditions, which brings stronger dynamic response and smooth performance to the vehicle.

the secret of adapting to various models: an in-depth interpretation of the practical application of 13011-87314A, 13011-87317 and 31032 specifications

this series of products covers the current mainstream Japanese, Korean and even domestic commercial diesel engines and other platform needs, whether it is a family car or transport trucks can be flexibly deployed. Each set is calibrated in strict accordance with the original equipment standard, ensuring that users can seamlessly connect to the original engine architecture with simple replacement.

The Power of Materials Science: How high quality Forging Extends Engine Life

the aviation grade alloy steel is selected as the basic raw material and modified by high temperature quenching and strengthening means, so that each part can withstand extreme temperature difference changes and high frequency vibration impact without deformation and aging. This deep optimization design greatly delays the arrival time of the subsequent secondary replacement cycle.

Behind the worry-free replacement experience: the reliability commitment brought by the original process

Thanks to the precise mold pressing technology and the support of the strict quality inspection system, each part delivered to the customer has reached a near-perfect accuracy error range. Even novice drivers who lack relevant experience can easily complete autonomous maintenance tasks under the guidance, and completely bid farewell to the repeated debugging troubles caused by incompatibility.

Reputation of Real Car Owners: Why it is the recommend Choice for Auto Repair Technicians

Feedback from front-line users shows that "since the piston ring of this brand was changed, the speed of the car has been faster and the noise has been significantly reduced", and positive comments like this have emerged one after another. Many senior technicians expressed their willingness to list it as one of the designated after-sales accessories in the store, which shows that the market recognition is extremely high.

Economic and environmental choice: double benefit analysis of reducing fuel consumption and reducing emissions

Good sealing performance helps to fully release the fuel energy utilization rate while effectively curbing the probability of the emission of harmful substances. Data show that the average fuel consumption per 100 kilometers after installing this component is generally reduced by about 5%-8%, while the exhaust gas detection data is cleaner and up to standard.

Installation skills are all open: step by step to teach you to successfully complete the piston ring upgrade

Although the whole operation involves the reorganization of precision components, in fact, it can be safely done as long as the special fixture is prepared and the instructions are gradually advanced. The key point is to pay attention to the direction identification and lubrication application link. Do not miss any step so as not to affect the smooth operation of the later stage.

comparative evaluation of on-site direct attack: DL-T F70V and other brands of the same type of products in actual combat